Sterile Manufacturing in 2024

Sterile Manufacturing in 2024

In an increasingly interconnected world, preventing contamination at every level specially manufacturing level is a must to avoid potential outbreaks of diseases linked to pharmaceuticals.

In the healthcare sector, every little thing is at high stake. Safety and Efficiency of the medications is very important as it affects the health and well being of the patients.

At Inject Care, we understand our role in the healthcare sector. To manufacture decontaminated, safe Penicillin and Cephalosporin we practice Sterile Manufacturing. Our unwavering commitment to sterility ensures that we continue to protect patient health, comply with regulatory standards, prevent cross- contamination, and maintain the trust of the global healthcare community.

The advancements in Sterile Manufacturing aim to ensure that the pharmaceutical industry continues to produce high-quality, safe sterile products, meeting the evolving regulatory standards and technological capabilities.

Why Sterile Manufacturing is not only important but essential too?

- Ensuring Patient Safety

- Maintaining Drug Efficiency

- Preventing Cross Contamination

- Enhancing trust and reputation

- Investment in Advanced Technology

- Regulatory Compliance

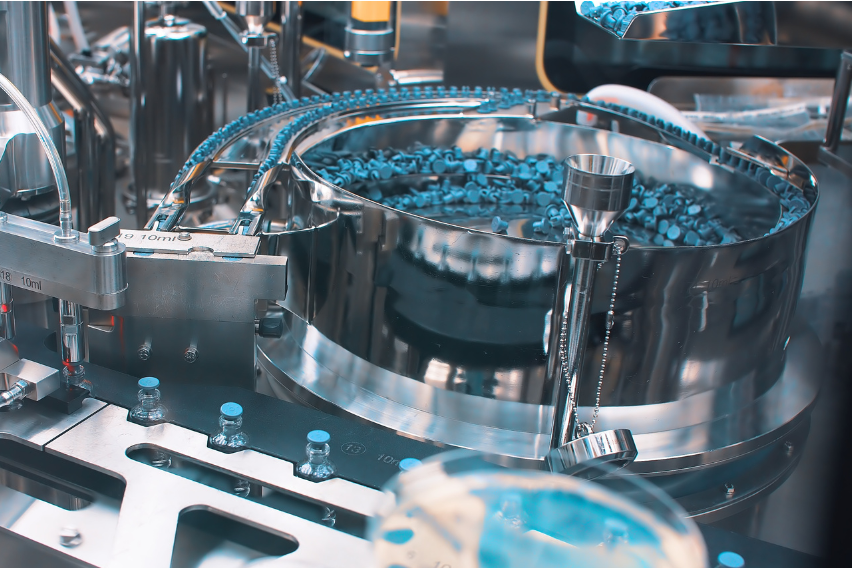

With time and advancing technology, Sterile Manufacturing Process is also evolving. Advancement in the Sterile Manufacturing has largely eliminated the involvement of human operators, reducing the risks associated with human contamination. So, What’s new in Sterile Manufacturing?

- Barrier Technologies:

There is a growing adoption of Restricted Access Barrier Systems (RABS) and isolators, which provide enhanced contamination control by physically separating the sterile environment from operators. These technologies are crucial in minimizing contamination risks during the production of sterile products .

2. Automation and Digitalization:

The integration of digital performance management practices, such as using analytics and root-cause-driven problem-solving, is helping manufacturers increase capacity without significant capital investments. Automation in sterile manufacturing processes is also reducing human intervention, thereby lowering contamination risks.

3. Modular and Flexible Manufacturing Systems:

Companies are increasingly using modular and flexible manufacturing systems, which allow for quick adaptation to different product types and batch sizes. These systems support continuous manufacturing and streamline processes to maintain sterility.

4. Single Use Technology:

A significant sterile manufacturing trend is the increasing use of single-use technology (SUT), which is a piece of technology intended for one-time use

5. Split Butterfly Valve usage :

This technology allows products to safely move from one vessel to another while maintaining sterility throughout the entire process

6. Real Time Monitoring :

Continuous, real-time monitoring of critical parameters such as non-viable and viable particulate counts and microbial levels allows for immediate corrective actions, reducing the risk of contamination. Advanced monitoring systems provide a more comprehensive understanding of cleanroom conditions.

A few Companies that have adapted and invested in Sterile Manufacturing :

1. Bora Pharmaceuticals’ Expansion:

- Bora Pharmaceuticals has expanded its North American footprint by acquiring Emergent

BioSolutions’ sterile manufacturing facility in Camden, Maryland. This acquisition enhances Bora’s sterile drug product manufacturing capabilities .

2. Pfizer’s New Sterile Injectable Facility:

- Pfizer is preparing to start operations at its new $465 million sterile injectable production facility in Portage, Michigan. This facility is designed with advanced

technology and will produce critical injectable medicines, enhancing Pfizer’s production

and supply capacity .

As the pharmaceutical industry continues to evolve, sterile manufacturing will remain pivotal in delivering safe and effective treatments to patients worldwide.